Proper Handling and Installation of APA Plywood Underlayment

One of the keys to good performance in floors is the right combination of subfloor, underlayment and finish flooring. Plywood Underlayment panels provide a smooth base for carpet, tile or sheet flooring and other types of finish flooring. APA Underlayment also resists dents and punctures from concentrated loads.

APA Rated Sturd-I-Floor® panels are specially designed as combination subfloor-underlayment. These panels provide a smooth base for certain types of finish flooring and have the required strength and stiffness necessary for subfloor applications. APA Rated Sturd-I-Floor is an excellent base for carpet and pad. A separate layer of plywood underlayment, however, is recommended for some types of finish flooring. Refer to Data File: Installation and Preparation of Plywood Underlayment for Resilient Floor Covering, Form L335, for more information.

TIPS FOR WORKING WITH APA PLYWOOD UNDERLAYMENT

1: Handling Underlayment.

Always protect plywood underlayment from moisture or damage prior to installation. Before installing, allow underlayment panels to acclimatize by standing them on edge and separating them to permit air circulation for several days in the rooms where they will be installed.

2: Installing Underlayment.

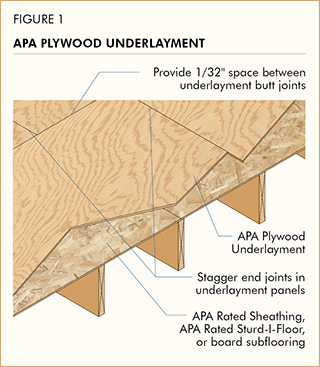

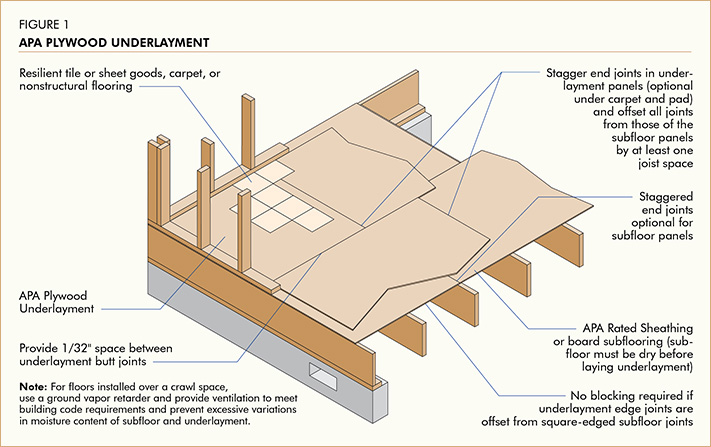

Plywood underlayment should be installed only on a dry subfloor. Inspect the subfloor for evenness along joints and flatness between joists. When necessary, sand the subfloor near joints; install extra blocking and re-fasten the subfloor to flatten uneven areas. Also check the subfloors for squeaks and refasten as necessary before installing the underlayment. Install plywood underlayment smooth side up. To avoid damage to the surface, install underlayment immediately before laying the finish flooring. For maximum stiffness, install underlayment with the face grain perpendicular to floor joists, and offset underlayment panel ends from subfloor panel ends by at least one joist space. All edge joints of the underlayment panels should be offset from the edge joints of the subfloor panels by at least two inches unless otherwise recommended by the finish flooring manufacturer. Space underlayment panels 1/32 inch at ends and edges.

OTHER IMPORTANT CONSIDERATIONS

1: Fasteners and Fastening Schedules.

Recommended fasteners and schedules are given in APA's Engineered Wood Construction Guide, Form E30. Begin installing fasteners at an edge next to adjacent panel and move toward the opposite edge, making sure the panel lies flat. Do not overdrive or underdrive fasteners. Overdriving can result in: "telegraphing" fastener or panel joint location through resilient tile or sheet flooring, or floor squeaks due to movement between underlayment and subfloor panels. Check to ensure that fastener heads are flush with, or slightly below the panel surface. Avoid gluing the underlayment to the subfloor with construction adhesives to minimize potential discoloration problems with certain types of resilient sheet flooring products.

2: Finishing and Filling.

Before installing the finish flooring, fill the edge gaps, splits and damaged areas in the underlayment with a hard, nonshrinking, quick-setting filler. (This step may not be necessary under some carpet and structural flooring products. Check the manufacturer's recommendation.) Lightly sand any surface roughness, particularly around fasteners.

3: Installing Finish Flooring.

When resilient sheet flooring is installed, consider "loose-laid," perimeter-attached flooring products to minimize exposure of plywood underlayment to moisture from water-based adhesives used for installing flooring; or choose premium-quality flooring adhesives with higher solids content and reduced water content and allow maximum "open" time within the manufacturer's recommendations before installing flooring. For other types of finish flooring, follow the flooring manufacturer's recommendations for installation.

ADDITIONAL INFORMATION

For additional information, including selection of Underlayment, installation guide, and fastener recommendations, visit the APA Publication Library and refer to the following APA publications:

- Engineered Wood Construction Guide, Form E30

- Selection, Installation and Preparation of Plywood Underlayment, Form L335

- APA Performance Rated Panel Subfloors Under Hardwood Flooring, Form R280

- Ceramic Tile Over Wood Structural Panel Floors, Form TT-006

Download Builder Tips: Proper Selection and Installation of APA Plywood Underlayment (PDF)