Siding and trim attachment without needing to hit studs. Meet code requirements and simplify fastening of siding and trim to plywood or OSB. Continuously sheathing with OSB or plywood not only makes walls stronger and more resilient—these structural panels also make a solid, consistent surface for attaching siding and trim that meets the requirements of the IRC.

Learn More >

Construct homes that balance structure, energy efficiency and cost. Advanced framing is a system of framing techniques based on optimizing building materials to produce wood-framed buildings with lower material and labor costs than conventionally framed structures.

Learn More >

Resist lateral and uplift loads at raised-heel trusses. Raised-heel trusses, also known as energy-heel trusses, deliver cost-effective energy performance, especially when used with continuous plywood or OSB sheathing.

Learn More >

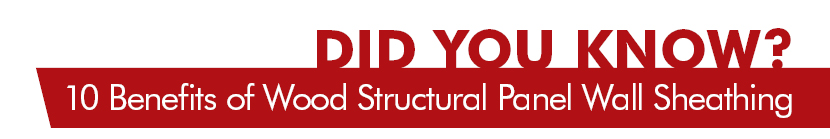

Simply comply with IRC wall bracing requirements. A house must be built to safely resist the lateral loads that result from high-wind events and earthquakes. Wall studs alone can't resist the racking forces. Wall bracing helps keep walls square during wind events and earthquakes.

Learn More >

Provides a rigid base for use with high density wall insulation. Wood structural panel sheathing maintains the structural durability of the home and allows walls to be insulated to higher R-values, resulting in high strength wall systems that are cost effective and contractor friendly.

Learn More >

Cost effectively comply with energy code requirements. Satisfy energy codes and construct energy-saving buildings in all climate zones.

Learn More >

Code-recognized air barrier material for sealing homes tight. Plywood and OSB sheathing are both code-recognized air barrier materials. Common sources of air infiltration should be checked and sealed during construction to minimize air leakage.

Learn More >

Construct homes that stand up to high wind and bounce back from earthquakes. Wood is the resilient choice for construction. Wood's strength combined with its ability to absorb stresses or impacts without weakening or degrading make wood a superior building materials, especially in areas susceptible to severe weather conditions or seismic activity.

Learn More >

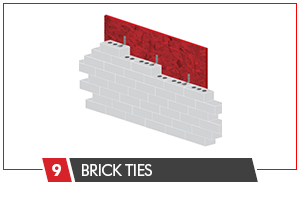

Easier brick tie attachment to sheathing without the need to hit a stud. Continuously sheathed OSB or plywood walls are a convenient and structurally sound base for attaching brick ties.

Learn More >

Strong, long lasting and environmentally friendly. Wood has many attributes that make it a good choice for building with an interest in environmental impact and green building.

Learn More >