APA Performance Rated I-Joists Storage, Handling and Safety Recommendations

To assure optimum performance and safe handling, APA trademarked I-joists must be stored and applied properly. The following guidelines will help protect joists from damage in storage, during shipment, and on the construction site, and protect the installer from job site injury.

To assure optimum performance and safe handling, APA trademarked I-joists must be stored and applied properly. The following guidelines will help protect joists from damage in storage, during shipment, and on the construction site, and protect the installer from job site injury.

Storage and Handling

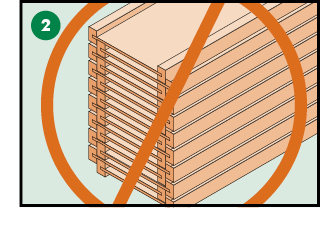

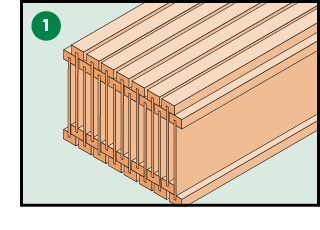

- Store, stack and handle I-joists vertically and level only.

- Do not store I-joists in direct contact with the ground and/or flatwise.

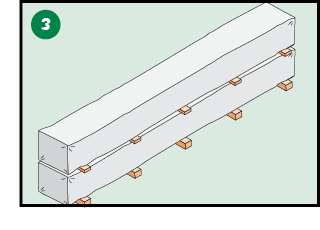

- Protect I-joists from weather, and use stickers to separate bundles.

To further protect I-joists from dirt and weather, do not open bundles until time of installation.

To further protect I-joists from dirt and weather, do not open bundles until time of installation.- Take care not to damage I-joists with forklifts or cranes.

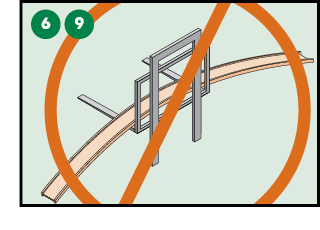

- Do not twist or apply loads to the I-joist when horizontal.

- Never use or try to repair a damaged I-joist.

- Except for cutting to length, I-joist flanges should never be cut, drilled or notched.

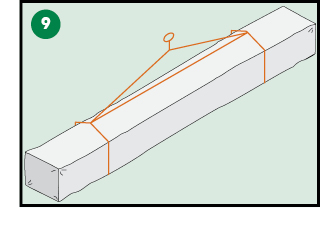

- When handling I-joists with a crane on the job site (“picking”), take a few simple precautions to prevent damage to the I-joists and injury to your work crew.

- Pick I-joists in bundles as shipped by the supplier.

- Orient the bundles so that the webs of the I-joists are vertical.

- Pick the bundles at the 5th points, using a spreader bar if necessary.

Safety Tips

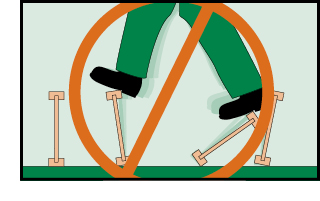

- I-joists are not stable until completely installed, and will not carry any load until fully braced and sheathed.

- Do not allow workers to walk on I-joists until joists are fully installed, sheathed and braced, or serious injuries can result.

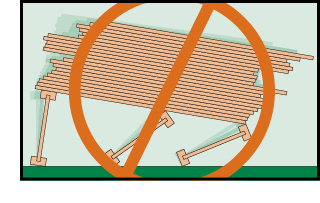

- Never stack building materials over unsheathed I-joists. Stack only over beams or walls.

Avoid Accidents by Following These Important Guidelines

- Brace and nail each I-joist as it is installed, using hangers, blocking panels, rim board, and/or cross-bridging at joist ends. When I-joists are applied continuous over interior supports and a load-bearing wall is planned at that location, blocking will be required at the interior support. See APA Builder Tips: Blocking for I-Joist Systems, Form A750, for more GET >.

- When the building is completed, the floor sheathing will provide lateral support for the top flanges of the I-joists. Until this sheathing is applied, temporary bracing, often called struts, or temporary sheathing must be applied to prevent I-joist rollover or buckling.

Temporary bracing or struts must be 1x4 inch minimum, at least 8 feet long and spaced no more than 8 feet on center, and must be secured with a minimum of two 8d nails fastened to the top surface of each I-joist. Nail bracing to a lateral restraint at the end of each bay. Lap ends of adjoining bracing over at least two I-joists.

Temporary bracing or struts must be 1x4 inch minimum, at least 8 feet long and spaced no more than 8 feet on center, and must be secured with a minimum of two 8d nails fastened to the top surface of each I-joist. Nail bracing to a lateral restraint at the end of each bay. Lap ends of adjoining bracing over at least two I-joists.- Or, sheathing (temporary or permanent) can be nailed to the top flange of the first 4 feet of I-joists at the end of the bay.

- For cantilevered I-joists, brace top and bottom flanges, and brace ends with closure panels, rim board, or cross-bridging.

- Install and fully nail permanent sheathing to each I-joist before placing loads on the floor system. Then, stack building materials over beams or walls only.

- Never install a damaged I-joist.

- Failure to follow applicable building codes and span ratings, failure to follow allowable hole sizes and locations, or failure to use web stiffeners when required can result in serious accidents. Follow these installation guidelines carefully.

Download a PDF version of these I-joist storage tips GET >

Additional Recommendations

For more information, refer to APA Technical Note: Proper Storage and Handling of I-Joists and LVL, Form E705 GET >