Satisfy energy codes and construct energy-saving buildings

We offer several resources on energy code compliant construction. The Performance Path is a tradeoff-based method to meeting residential energy code by trading out components, offering builders cost savings. IECC Compliance Options for Wood-Frame Wall Assemblies is an illustrated design guide offering detailed information on construction walls with R20 or better values. Also, watch our video on ENERGY STAR® Home Certification.

IECC-Compliant Wood-Frame Wall Assemblies > ENERGY STAR® video >

The Performance Path

When new energy codes are introduced, the biggest concern for builders is often the cost impact of any changes. The IECC has become stricter since its introduction by the International Code Council, resulting in significantly reduced overall energy usage in buildings. At the same time, however, the IECC has also evolved to permit greater flexibility for buildings, allowing different methods, or "paths" to demonstrate compliance. Using a performance approach to code compliance lends maximum flexibility to meet or exceed the energy code in the most cost-effective manner.

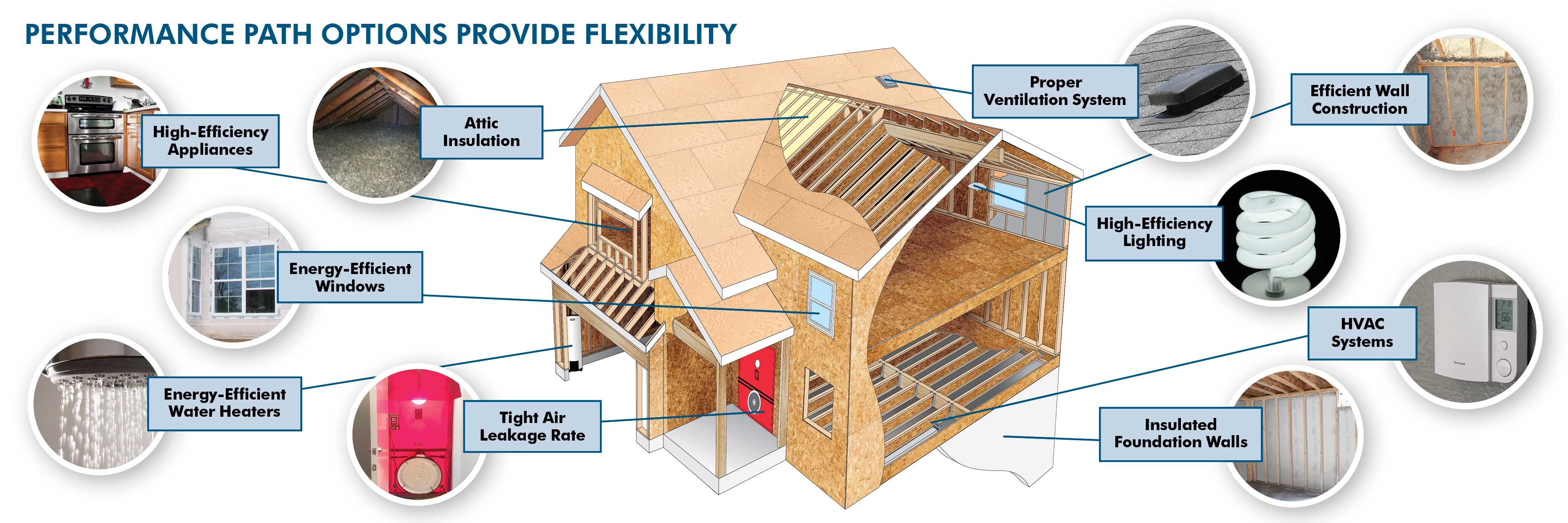

What is a Performance Path?

A performance path uses energy modeling to demonstrate that the building as a whole uses equal or less energy than a home built using the prescriptive path. The performance path allows flexibility to trade out of many of the high-cost assemblies required in the prescriptive path, while delivering a home that is more energy-efficient from top to bottom.

The Performance Path to Energy Code Compliance, Form R505, offers an introduction to two of the most cost-effective ways to comply with the International Energy Conservation Code (IECC). The Simulated Performance Alternative (performance) and Energy Rating Index (ERI) compliance paths allow builders to value-engineer energy efficiency by viewing the entire home as a system, getting more bang for the buck by trading out high-cost building assemblies for less expensive, energy-efficient assemblies and systems elsewhere in the building.

DOWNLOAD NOW >

IECC Compliance Options for Wood-Frame Wall Assemblies Updated for 2018 IECC

IECC Compliance Options for Wood-Frame Wall Assemblies, Form P320, has been updated by APA and the International Code Council (ICC) to include several examples of wood-frame wall assemblies that comply with the R20 and R13-5 prescriptive requirements of the 2009, 2012, 2015 and 2018 International Energy Conservation Code (IECC). The publication provides tips and recommendations that help builders construct energy-code-compliant wood walls using continuous wood structural panel wall sheathing.

Available as a free download, this guide describes how energy performance is measured in exterior wood wall assemblies and how to improve wall thermal performance to meet energy code requirements. Also provided are recommendations for reducing material costs by increasing the use of lower-cost cavity insulation, optimizing material usage with easy-to-apply advanced framing techniques, and boosting thermal performance with insulated headers and siding.

DOWNLOAD NOW >

ENERGY STAR® Home Certification: Advanced framing techniques for comfortable, efficient homes

In the ENERGY STAR® Home Certification video, Engineered Wood Specialist Matt Brown describes the process for ENERGY STAR home certification, and how home builders can strike an optimal balance between energy efficiency, structural performance, and affordability through using advanced framing methods. Running time about 4 minutes.

Energy Efficiency and Advanced Framing

Adopting advanced framing is a cost-effective way to meet or exceed energy code requirements. Simultaneously maximizing space for cavity insulation while minimizing the potential for insulation voids, advanced framing delivers significant energy performance — and cost savings for the builder. As energy codes have become increasingly stringent, advanced framing has grown more popular in climate zones where high prescriptive wall R-values are mandated or desired. While framing with 2x6 studs spaced 16 inches on center is already common in many northern states with more restrictive energy demands, increasing stud spacing to 24 inches on center, insulating effectively, and fully sheathing with wood structural panels, such as plywood or oriented strand board (OSB), allows builders to cost-effectively balance energy and structural code requirements.

ENERGY STAR® and Advanced Framing

ENERGY STAR® and Advanced Framing

The ENERGY STAR® program was developed by the U.S. Environmental Protection Agency to promote the use of energy-efficient products and practices. Advanced framing can help builders meet the requirements necessary to earn the ENERGY STAR label for new homes. For more information on the ENERGY STAR program, visit www.energystar.gov.