Spring 2018

Highlights from this Month's e-Newsletter

- Feature—Measuring the Environmental Performance of Engineered Wood Products

- Getting Technical—Fire Phraseology FAQs: FRT versus Fire Rating

- Inside the Circle—Advancements in Force Transfer Around Openings for Wood-Framed Shear Walls

Feature

Measuring the Environmental Performance of Engineered Wood Products

“Green” is just a buzzword unless environmental impacts can be demonstrated scientifically. One of the most commonly accepted methods of analyzing a product’s environmental impacts is LCA.

What is LCA?

Life cycle assessment (LCA) is a comprehensive measure of the total environmental impact of a product, assembly, or structure. True to its name, LCA is a holistic measure that examines the entire life cycle of a product, start to finish. Life cycle assessment measures energy expended during all aspects of service life, encompassing raw material extraction, manufacture, distribution, use, maintenance, and disposal.

Wood’s environmental impacts versus other materials

LCA measurements show that solid wood and engineered wood consistently outperform steel and concrete in terms of environmental sustainability. Wood’s numerous comparative advantages include less energy consumption during production, less greenhouse gas emissions, less air and water pollution, and less solid waste production.

A 2015 Australian study compared the life cycle environmental impacts of two apartment structures, one constructed with a lightweight timber frame and the other with concrete. The study measured factors ranging from greenhouse gas emissions to release of chemicals which contribute to acid rain. The wood structure scored better in three of the five categories, with the majority of the impacts occurring during an assumed 60-year service life. The study concluded that wood construction provides a more environmentally friendly building option over the life of a building. The study also found that much of the environmental advantage of the wood option was due to its lightweight design—a design benefit that offers many advantages, including cost savings. (Forest & Wood Products Australia, “A Comparative Life Cycle Assessment of Two Multi Storey Residential Apartment Buildings," July 2015)

Not without critics

LCA has been criticized by some for its focus on energy use at the expense of other considerations, such as toxicity or social justice. At the same time, analysis of energy use is complicated enough in itself, and some of those considerations are quite difficult to quantify in a mathematical model. Despite its critics, LCA has become a widely accepted analysis of cradle-to-grave environmental impact of building materials.

LCA tools

Two popular tools for estimating LCA include the Athena Environmental Impact Estimator and the Building for Environmental and Economic Sustainability (BEES) software, which also includes an economic performance score.

Environmental Product Declarations (EPDs) and EPD Transparency Briefs

Even with advanced LCA tools, sustainability is sometimes difficult to quantify. Environmental Product Declarations (EPDs) provide building teams with science-based information on environmental impacts to facilitate more informed building material choices.

In compliance with ISO 14025, Environmental Labels and Declarations, an EPD gives a third-party verified evaluation of a product’s environmental performance, including global warming potential, primary energy consumption, material resources consumption, non-hazardous waste generation, acidification potential, smog potential, and other measures.

Because EPDs are often lengthy, EPD Transparency Briefs were developed to provide a shorter, more readable summary of the most critical data in an EPD: the third-party verified, life-cycle based product data that is used in green building certification and rating systems.

The American Wood Council (AWC) publishes EPDs and EPD Transparency Briefs for LVL, wood I-joists, softwood plywood, OSB, glulam, softwood lumber, and other wood products.

View EPD's >

APA Green Verification Reports

APA Green Verification Reports help building officials and design professionals determine a product's eligibility for points under recognized green building standards.

Green Verification Reports consist of a checklist designed to help document the compliance of individual engineered wood products manufactured under a quality program audited by APA to specific international, national, or industry recognized green building standards, including ICC 700-2015, ICC 700-2012, ICC 700-2008, LEED v4, 2009 LEED, and 2009 LEED Canada.

Go >

Sustainable Building, Sustainable Future

APA's environmental brochure, Sustainable Building, Sustainable Future, Form F305, describes the environmental benefits of engineered wood products, compares wood to other structural products, and explains scientific research that demonstrates wood's green building merits.

Download >

Getting Technical

Fire Phraseology FAQs: FRT versus Fire Rating

Fire resistant, fire retardant, fire rating: what’s the difference? Here’s a quick explanation of some commonly used fire safety terms and their implications for building construction.

Fireproof? Probably Not.

Because most inhabited buildings have flammable contents and furnishings, there’s no such thing as a truly “fireproof” building. If these contents catch fire, they can quickly generate enough smoke and heat to cause extensive damage.

While “fireproof” is probably not attainable, fire resistant construction is well within reach. Extensive testing of building components and systems has resulted in UL-certified fire-rated assemblies that retain the structural ability to contain a fire long enough for inhabitants to escape.

Fire Resistance Rated (Fire Rated) Assemblies

A fire resistance rating, often shortened to “fire rating,” measures the length of time that a structure can continue to perform its function when exposed to fire. The rating is determined through testing methods prescribed in the building code and is expressed as an “X”-hour fire resistance rated assembly.

For example, a UL listed one-hour fire rated floor assembly, properly built to specification, will support its design load without collapsing or transmitting flame and high temperatures for at least one hour after a fire commences.

Some building products, such as glulam, may also carry a fire rating. But do not confuse fire rating with fire retardant treatment (FRT); the two are in no way equivalent.

Fire Retardant Treated (FRT) Wood

A variety of wood products are available with fire retardant treatments (FRT), a pressure impregnation process that forces a flame-inhibiting substance into the wood fiber. This treatment inhibits flame spread across the surface of the wood, which may qualify for a reduced fire hazard classification—and yet, this does not necessarily impact fire rating.

False Equivalency: FRT ≠ Fire Rating

Fire retardant treatment is mostly helpful for containing smaller, cooler fires, as it retards surface flame spread. But, at a high enough temperature, FRT doesn’t make much of a difference. Flame spread inhibition becomes irrelevant if the fire is very hot or very large, and FRT treatment does little to contain damages under these conditions.

Glulam and Fire

Glulam performs very well in the intense heat of a fire, where temperatures can reach 1,650 degrees Fahrenheit or higher. Unprotected steel members typically buckle and twist in such high temperatures, causing catastrophic collapse of both the roof and supporting walls.

Wood ignites at about 450 to 500 degrees F, but charring may begin at 300 degrees F. Wood typically chars at a rate of 1-1/2 inches per hour; after 30 minutes of fire exposure, only the outer 3/4 inch of glulam will have sustained fire damage. The adhesives used in the glulam burn at about the same rate as the wood and do not affect the overall fire performance of the glulam. And the char that develops insulates the glulam; most of a large glulam will remain intact when exposed to fire, and the member can continue to support the load of the building.

Depending on the severity of the fire and after a structural re-analysis by a qualified design professional, it is often possible to salvage the glulam members by merely removing the fire-damaged material and refinishing the surface of the member.

Fire-Rated Glulam

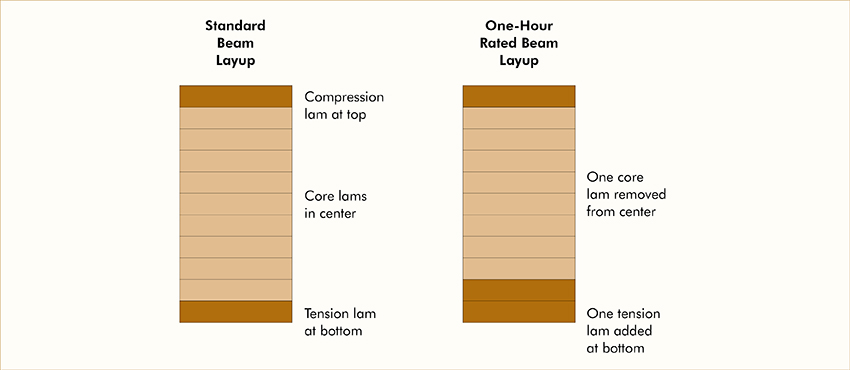

A structural member’s fire resistance is measured by the time it can support its design load during a fire. An exposed beam or column sized for a minimum one-hour fire resistance will support a design load for at least one hour during standard fire test conditions which simulate an actual fire. To qualify for a one-hour fire rating, a glulam will be manufactured differently, with the core lamination adjacent to the tension lamination replaced by a second tension lamination. As with all other structural framing, specifications of one-hour fire resistance rated glulam should be checked by a professional designer to assure compliance with local codes.

Download Technical Note: Calculating Fire Resistance of Glulam Beams and Columns, Form Y245, for more detailed information.

Fire Retardant Treated Glulam

While APA doesn’t currently recommend FRT glulams, we understand there are some treaters producing this material. As treatment may cause checking or other impacts on the strength and stiffness of the glulam, designers should request a code report for approval.

“Fire Rated Plywood” is NOT a Thing, but FRT Plywood is

Plywood is not a fire rated product. If someone says “fire rated plywood,” they probably are referring to the product known as FRT plywood.

When treated in accordance with AWPA Standard U1, FRT plywood qualifies for a lower flame spread rating—at least as low as gypsum wallboard—and has a reduced fire hazard classification. Nonetheless, FRT plywood cannot be substituted for gypsum wallboard in listed fire rated assemblies. Despite slowing surface spread of flame, fire retardant treatment has little effect on the rate at which plywood will degrade through its thickness when subjected to an elevated heat source. Never substitute FRT materials for other materials with a similar fire hazard classification in a UL fire rated assembly.

For more information on FRT plywood, including code references outlining where FRT may be used in lieu of noncombustible materials, such as exterior sheathing in Type III walls, download Technical Note: Fire Retardant Treated (FRT) Plywood, Form K320.

For more information on Fire Rated Assemblies, download Fire Rated Systems, W305.

Released in 2017: Uniform Vertical Load Capacity of Glulam Rim Boards® Subject to Fire Exposure

This APA Technical Topic reports the results of a series of mechanical property tests to verify the design uniform vertical load (UVL) capacity that glulam Rim Boards can carry after 1 or 2 hours of fire exposure.

Download Uniform Vertical Load Capacity of Glulam Rim Boards® Subject to Fire Exposure, Form TT-124.

Now Updated: Fire-Resistance-Rated Wood Floor and Wall Assemblies—DCA 3

The American Wood Council (AWC) recently updated Design for Code Acceptance (DCA) 3, Fire-Resistance-Rated Wood Floor and Wall Assemblies, which describes how interior and exterior wood-frame walls and wood I-joist floors can be used to meet building code requirements for fire-resistance-rated assemblies. The Design for Code Acceptance Series is free to download; visit AWC's "Fire Safety" webpage for DCA and many other fire safety resources.

Visit >

Archived Newsletters

Summer 2019 GO >

Spring 2019 GO >

Winter 2019 GO >

Summer 2018 GO >

Spring 2018 GO >

Autumn 2018 GO >